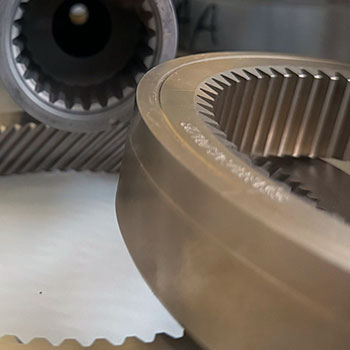

Straight and bevelled spider

Internal toothing spherical butted

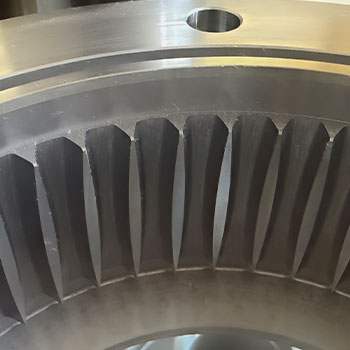

Internal toothing, straight cut

Internal splines pushed straight

Internal gears are gears in which the teeth are mounted on the inside of a hollow cylinder or ring. They are typically used in planetary gears or special constructions. The tooth profile usually corresponds to that of involute gearing in order to enable standardised pairing with external gears.

Internal gears are manufactured using processes such as gear shaping or grinding. Due to the internal geometry, their production is more complex than that of external gears.

Internal gears enable particularly compact designs, as the gearing can be integrated into the housing or into ring gears. The enclosing profile improves running smoothness as vibrations can be better damped.

If internal gears are shanked, a further advantage is that the gearing can be interrupted up to a certain point in the gear width, in contrast to broaching or eroding.

Internal gears are ideal for planetary gearboxes where high torque density and centric power transmission are required. They also offer design freedom in the arrangement of bearings and sealing elements.

We offer our customers the following benefits:

Components with internal gearing manufactured according to customer specifications

Comprehensive quality control by measuring the manufactured components

Flexible production and short delivery times

Using measuring machines, our Gleason gear measuring centres or 3D measurements with Zeiss-Contura, we test and measure your components precisely and in accordance with standards. An air-conditioned measuring room ensures stable conditions such as temperature and humidity and delivers reproducible results. In this way, we ensure the quality of your components from the initial sample inspection to the final inspection.